By Erns Wall, Interior Designer

As an Interior Designer, I rely on information provided by manufacturers and third-party certification agencies to make decisions about the furniture, equipment, fixtures and finishes I specify for projects. Some types of information are standardised across the industry, such as fire ratings for products and assemblies, or the coefficient of friction on a floor tile. Other types of information like data specifically related to environmental sustainability can be more difficult to source.

Manufacturers have become increasingly transparent about disclosing the fabrication processes and contents of their products, especially as they relate to helping projects achieve LEED credits and other marketable evaluation criteria. While this type of information is invaluable, it paints an incomplete picture of how sustainable a project is based on the sum of its parts. In order to gain a more holistic understanding of sustainability, additional metrics and evaluation methods need to be considered. One of the most widely used methodologies is Life-Cycle Analysis (LCA), and more specifically embodied energy.

Embodied energy is the total energy inputs consumed throughout a product’s life-cycle, and by extension, its environmental impact. At first glance it appears fairly straight forward – tally the energy inputs for harvesting and manufacturing resources, transporting, and assembling building materials to construct a new building or refurbish an existing one. Additionally, recurring embodied energy refers to energy consumed to maintain or repair building materials or systems.

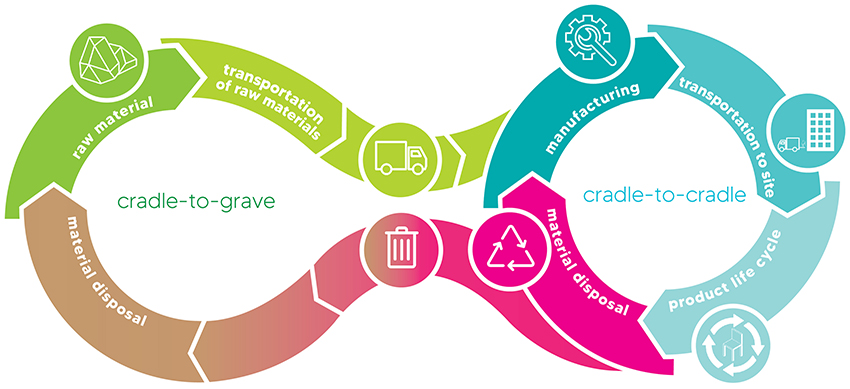

Life-Cycle Analysis looks at the environmental impact associated with all stages of a commercial product, ending in its disposal. Typically, this is referred to as a Cradle-to-Grave cycle in which a product is disposed of at the end of its useful life and is replaced by a new product. In a more sustainable Life-Cycle variant called Cradle-to-Cradle, a product is recycled into the same product (such as glass bottles made from recycled glass bottles) or different products (such as glass wool insulation made from recycled glass bottles).

While it is ethically and environmentally responsible to specify products that are recyclable beyond their intended lifespan, a project’s design team is typically not involved with the disposal of building materials at the end of their lifespan. Furthermore, a lot of recyclable materials end up in landfills because the infrastructure to deconstruct, sort, and process various materials and assemblies is not readily available or is cost-prohibitive. Because of this, interior designers, architects and specifiers should prioritize products that are made from recycled materials and have low embodied energy wherever possible, in addition to being recyclable.

Images: Repurposing and reusing existing materials helps to reduce the embodied energy of a project. At the University of Winnipeg’s Richardson College for the Environment and Science Complex (left), Number TEN repurposed the hardwood flooring from a neighbourhood roller rink that formerly stood on the site. In our office renovation (right), we re-used the glass fronts, cedar lintel and furniture from the partners’ offices for a collection of meeting rooms.”

It is relatively easy to figure out that some materials and finishes are more environmentally sustainable than others based on their properties. For example, it’s easy to understand that acrylic is more energy intensive to manufacture and transport than cork when comparing them by volume. However, when comparing acrylic and glass, it becomes less clear because they are both energy intensive to manufacture and are heavy to transport.

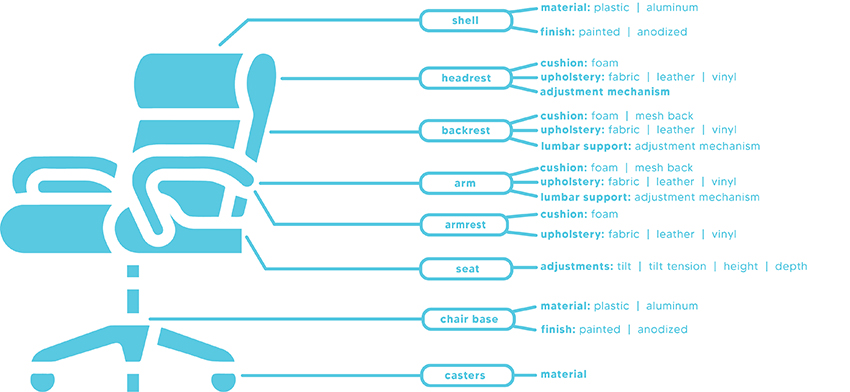

Things get complicated when you dissect more complex products and assemblies into their component parts. For example, standard task chairs appear simple because of how ubiquitous they are and since many of us sit in one for the majority of our workday, they become ‘ordinary’. Once broken down into their component parts, the numerous materials and mechanisms that make up standard chairs become more visible. This complexity is illustrated below.

Calculating the embodied energy of even one of the components can become a huge task. Many questions arise such as: How was the aluminum mined and refined? Which energy source does the fabric mill consume? Does a higher foam density in the cushion mean that it’s manufacturing process is more energy intensive? Will a task chair that’s specified based solely on a sustainability scorecard perform as well as one that isn’t?

Full disclosure: I don’t have the answer to any of these questions. Luckily, a growing number of manufacturers are doing the work involved in figuring out exactly how much embodied energy their products contain in the form of Environmental Product Declarations (EPDs). This information is accessible through the Environmental Product Declaration Database. As this is a relatively recent initiative and completely voluntary, the database does not have EPDs for the majority of commonly specified products but it is steadily growing.

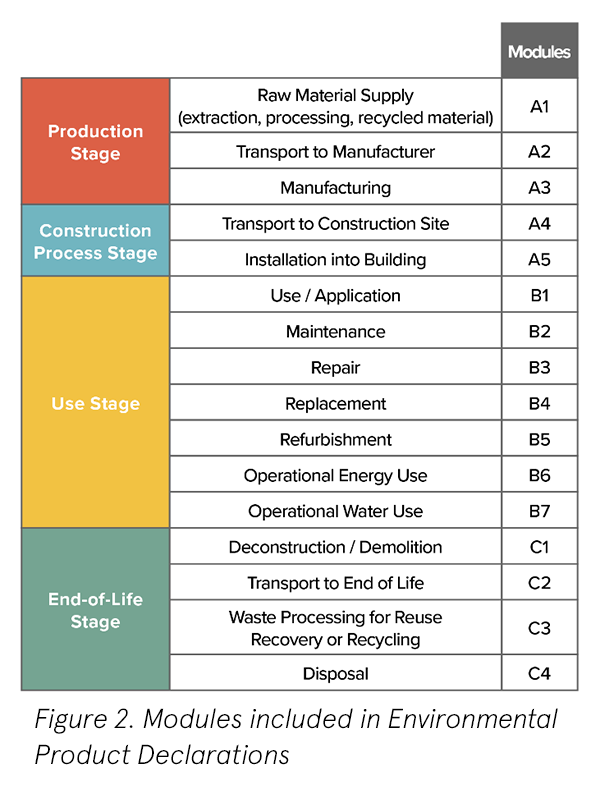

If you take a look at a commonly specified product, you’ll see that its EPD contains a large volume of information including its potential environmental impact, use of resources, waste production, and output flows through all of the Cradle-to-Grave stages. While  I applaud the transparency and efforts of the manufacturer, the data is presented in EPDs is difficult to understand. Additionally, data for all 16 modules in an EPD (Figure 2) is displayed separately, which is great if you’re looking for specifics such as how much carbon dioxide is produced during the production stage of a product. If you want to know how much carbon dioxide is produced throughout a product’s entire life-cycle, you’ll need to manually tally up all 16 stages. If you need to make comparisons between products, you’ll have to go through that process for each product, which is time consuming and not really feasible for designers with limited resources and working on deadlines.

I applaud the transparency and efforts of the manufacturer, the data is presented in EPDs is difficult to understand. Additionally, data for all 16 modules in an EPD (Figure 2) is displayed separately, which is great if you’re looking for specifics such as how much carbon dioxide is produced during the production stage of a product. If you want to know how much carbon dioxide is produced throughout a product’s entire life-cycle, you’ll need to manually tally up all 16 stages. If you need to make comparisons between products, you’ll have to go through that process for each product, which is time consuming and not really feasible for designers with limited resources and working on deadlines.

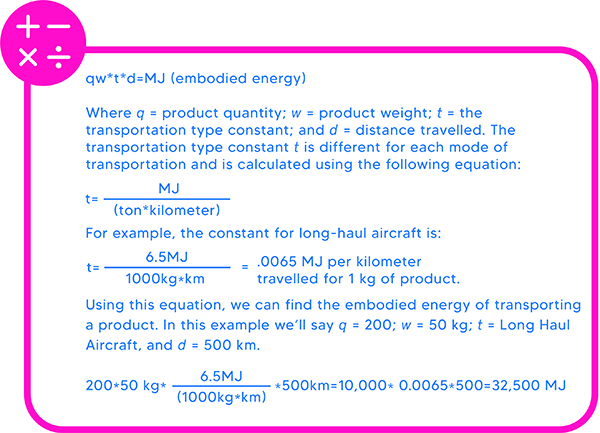

Due to my frustration with sourcing sustainability-related data for interior design finishes and assemblies, I’m trying to find simpler ways to make informed decisions when comparing equivalent products. Ultimately, this has led to a geography- and transportation-based calculation. Admittedly, the idea of sourcing locally is certainly not a new one. However, it’s useful when comparing equivalent products and being able to show clients real numbers when you’re taking meaningful steps to reduce the environmental impact of a project. All you really need to know is where a product was manufactured and how it gets to the construction site, along with the product’s weight. In life-cycle analysis, this is the gate-to-site stage.

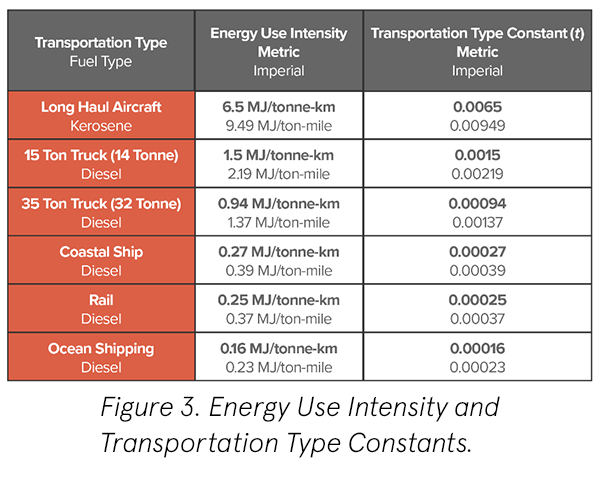

For the purpose of my calculations, I’m referencing embodied energy constants for different transportation types as published in Cannon Design’s Embodied Energy presentation. The equation (see below) produces a number expressed in megajoules, which is a unit of energy commonly used to describe embodied energy.

If the same product were to be transported by rail, we would use t = 0.00023 and the equation would total 1,150 MJ for the same product travelling the same distance. To put these numbers into perspective, the average Canadian household consumes 92,500 MJ of energy per year so it’s easy to see how the energy used to transport construction products very quickly adds up. The table below lists the constants for common transportation types.

Using this equation, it is easy to understand how a project’s environmental impact can be influenced by the distance travelled and the type of transportation used to get materials from the factory to the construction site. This method is not intended to replace other evaluation methods when data is available, or when comparing products with dissimilar properties and manufacturing processes. However, the next time you’re having difficulties making a decision between two equivalent products, use this method to make a case for reducing the embodied energy of a project and go with the choice that’s less energy intensive.

Using this equation, it is easy to understand how a project’s environmental impact can be influenced by the distance travelled and the type of transportation used to get materials from the factory to the construction site. This method is not intended to replace other evaluation methods when data is available, or when comparing products with dissimilar properties and manufacturing processes. However, the next time you’re having difficulties making a decision between two equivalent products, use this method to make a case for reducing the embodied energy of a project and go with the choice that’s less energy intensive.